Representative 3D Modeling/Illustration/Animation Projects

So, how can you use my 3D modeling, illustration, and animation skills?

- Product "photos" before the product is in production;

- cut-away illustrations of products that can't be cut without destroying the components;

- "how it works " videos;

- product demonstrations;

- images, animation, or video for marketing and advertising;

- product conceptualization;

- total fantasy, utter fabrication, or outright visual lies!

I've been a big fan of computer-generated graphics from Hollywood for years; 3D modeling fasinates me. I understand the overall process, but I admit I am a babe-in-the-woods relative to what can be done, versus what I personally can do. Hollywood has no competition from me; still, I've been pretty successful with the projects I've done to date. And I'm always looking for an excuse to try something new and learn a bit more...

The cost of a 3D modeling project varies directly with the complexity of the objects to be created, the materials they are "made "from, the overall scene, lighting, and if animation is involved. I use AutoDesk Maya®, which is the same package the Hollywood Special Effects (SFX) industry uses. Models can be built simply, or can obey the laws of physics. They can represent the concept of an object, or be built to the same physical tolerances as the actual machine (the model for the first example below for LIST, was built to the same 0.001" tolerances as the real machine so it would behave exactly as the real machine does.)

3D Modeling/Animation Example: LIST (Switzerland) High-Viscosity Material Mixing Machine

|

The LIST high-viscosity material mixing machine is a perfect example of a project where the actual machine couldn't be physically cut to show it's inner workings. To support tradeshows and sales demos, LIST requested an animated video 3D cutaway of the machine. They supplied a set of engineering drawings which I used to create the outline drawings of the most critical IP components - the mixing discs, blades, and shafts. These outline drawings were imported into Autodesk Maya, where I built corresponding 3D model components. These components fit together the same way the actual machine components do - to the same ±0.001" tolerance. |

The LIST machine "claim to fame" is the dual mixing and self-cleaning actions of the specially-shaped, interlocking blades and mixing discs. Just a quick note on what you're looking at: the two shafts are heated, as is the outer jacket of the mixing chambers. If you'd like to see the full animation for this machine, this is the YouTube link... |

|

|

|

|

|

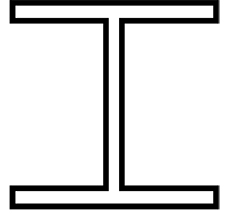

The cross-section of the main support i-beams. |

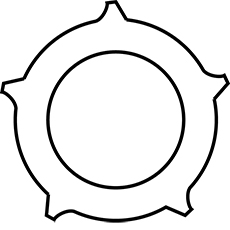

Part of the outer case cross-section. It's built from multiple pieces to get the proper shape. |

The mixing disc that is mounted to the heated shafts that has the mixing blades welded to it. The shape and angles are what allows the machine to do what it does. |

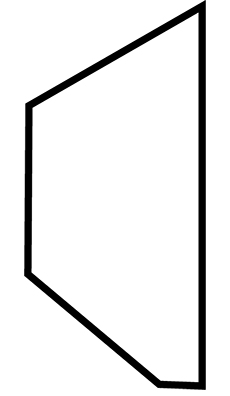

This is the end view of a blade. Ther's lots more geometry in the final blades. This was the base shape. |

Top of Page

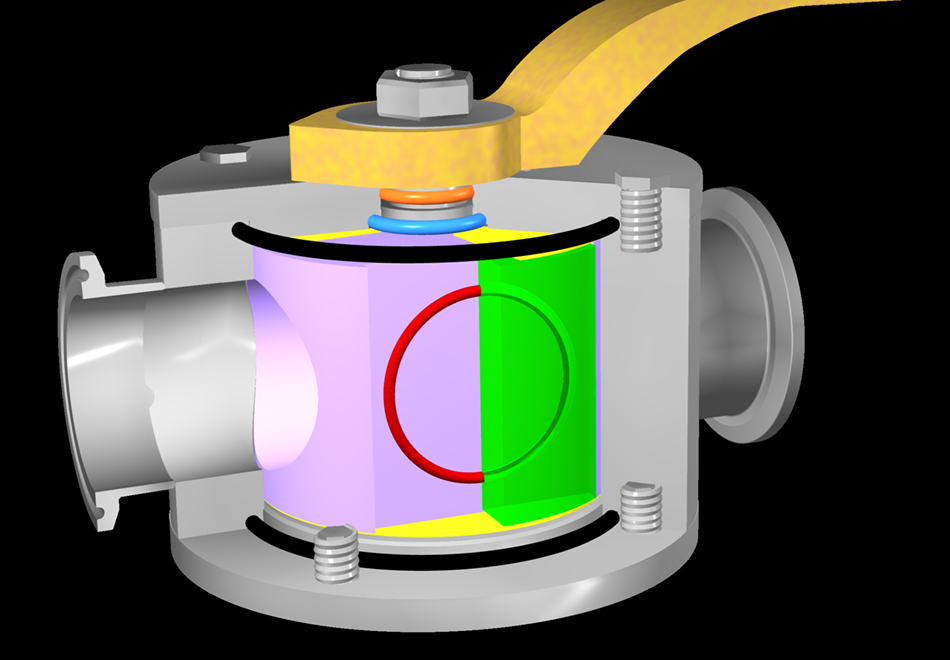

3D Modeling/Illustration Example: Valve Cutaway Illustration

|

This is another example of a product that would not survive a hacksaw to create a cutaway view of the internal structure. This is one of a series of valves that |

were modeled and rendered in different operating positions to show flow direction changes for product data sheets and tradeshow displays. |

|

Top of Page

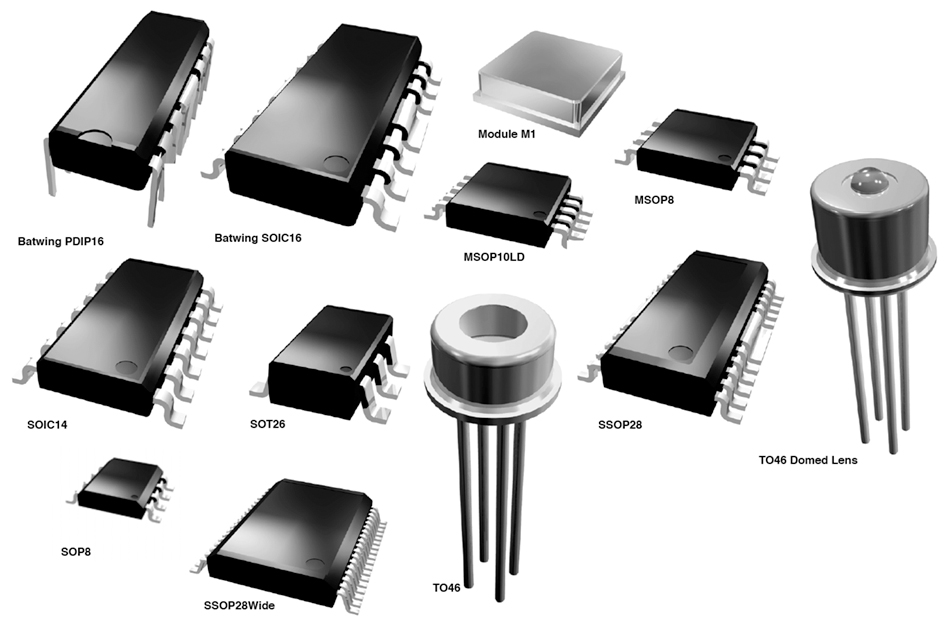

3D Modeling/Illustration Example: Integrated Circuit Packages

|

These model renderings were done to support product data sheets and press releases prior to product |

production. The models were built using engineering drawings of the packages. |

|

Top of Page

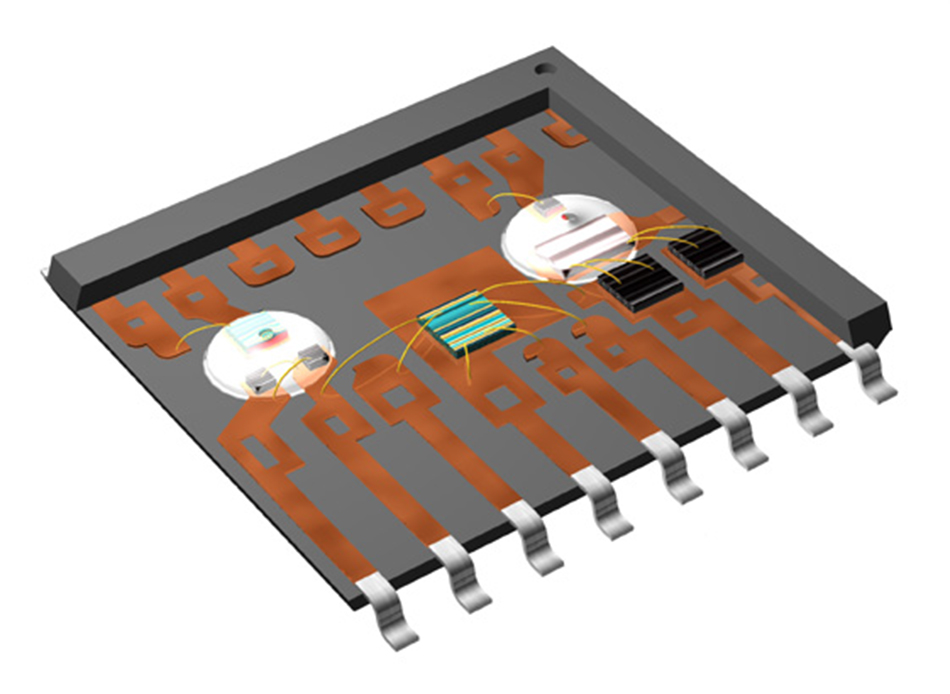

3D Modeling/Illustration Example: Internal Cutaway of Integrated Circuit (IC)

|

Still another example of why you need to keep the saws-all away from a product to do a cut-away. |

This one shows the inside structure of an opto-electronic IC. |

|

Top of Page

3D Modeling/Illustration Example: Telephone Headset on Human Head - Branding Image

|

This long-term client needed a branding image that would stand out. The model of the human head was purchased from a company no longer in business. I built the model of the telephone headset from engineering drawings. |

The resulting image became the branding image for the company and its various telephone and computer headset product lines. |

|

Top of Page

3D Modeling/Illustration Example: Advertising Image

|

Since it wasn't politically correct to color the human head models actual racial skin colors, it made sense |

to make them different colors in general, and then use the tag line "No Matter Who You Are..." |

|

Top of Page

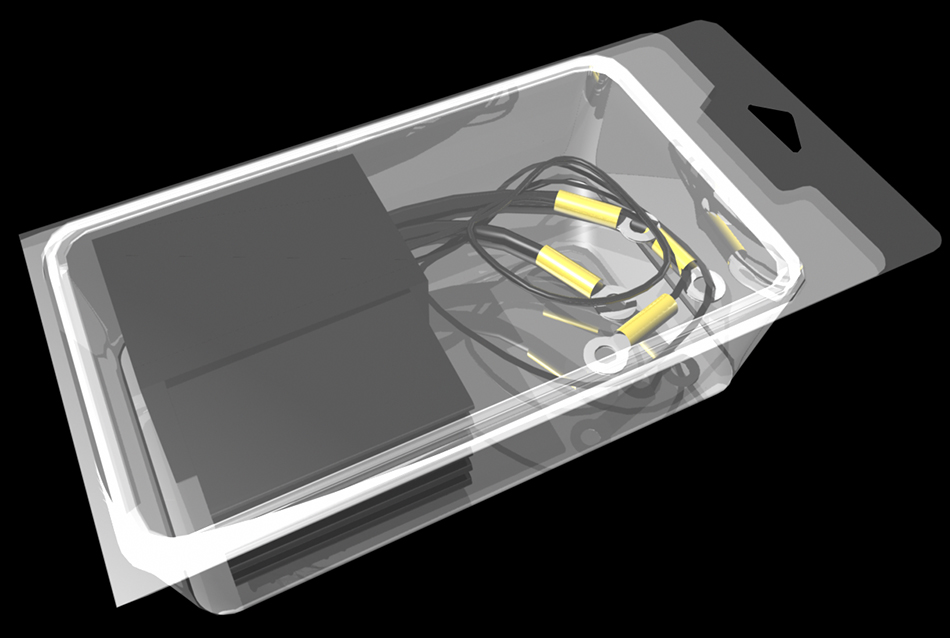

3D Modeling/Illustration Example: Retail Package Mockup

|

This is a retail packaging mockup for an after-market motorcycle battery monitoring system. The product and package were modeled separately and combined |

to show how the package would look before a printed blister card was attached. |

|

Top of Page

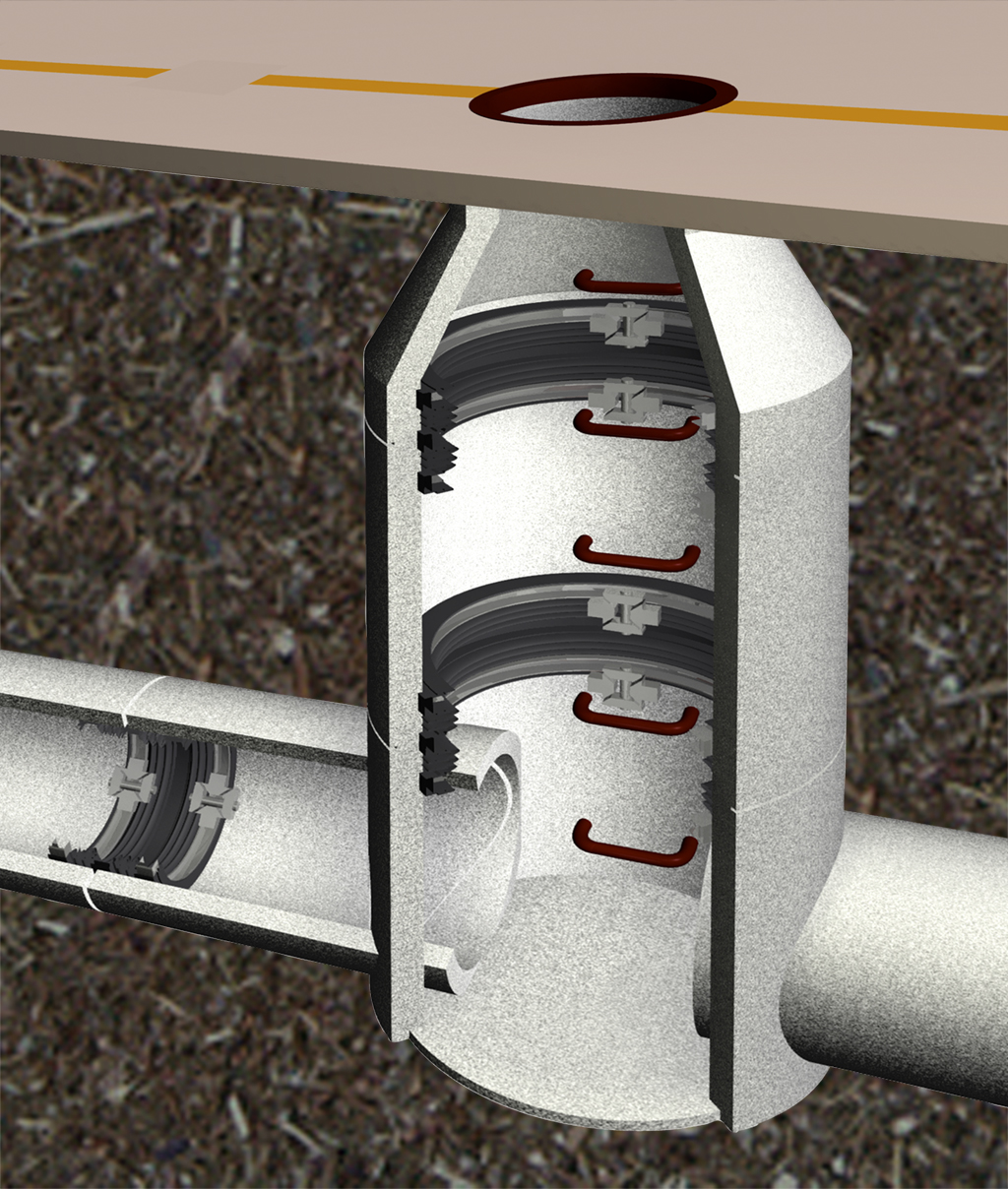

3D Modeling/Illustration Example: Concrete Drain Rubber Sealing System

|

This client made a rubber sealing system with a special wedge-shaped locking system - their Intellectual Property. An actual sewer drain pipe wasn't available - |

and frankly, I wasn't all that interested in being in one to shoot photos. A 3D model and rendering for an ad campaign was the simple solution. |

|